Above:

The Jazzman Mk III ESL

and Ripol Subwoofer

Note

This blog is a hobby, not a business. The author does not build speakers or components to sell. That said, drawings, parts lists and build tips are freely shared with other DIY'ers upon request to: Jazzman1953@gmail.com

Introduction

Greetings all from the Jazzman,

Greetings all from the Jazzman,

It still amazes me that an average Joe with practically no electronics experience can build a speaker at home that rivals the high-end commercial offerings, and bests most of them. Building the actual driver from scratch takes DIY to a whole new level.

Roger Sanders' Cookbook enabled my first ESL build in 2008, and my latest speakers would not have been possible without ESL gurus Calvin, Rod White, and Steve Bolser (a.k.a. Calvin, Golfnut and Bolserst at diyAudio) freely sharing their knowledge on the diyAudio Forum.

Roger Sanders' Cookbook enabled my first ESL build in 2008, and my latest speakers would not have been possible without ESL gurus Calvin, Rod White, and Steve Bolser (a.k.a. Calvin, Golfnut and Bolserst at diyAudio) freely sharing their knowledge on the diyAudio Forum.

Roger, Calvin, Rod, and Steve-- you guys are the best!

Although I'm no longer building speakers, I still enjoy helping others and I'm pleased to share my DIY electrostatic loudspeaker projects.

Charlie Mimbs

Savannah, GA

The Jazzman MkIII

This speaker is the culmination of 15 years designing and building ESLs. Its 69 hardwood details are solid rift-sawn red oak assembled with interlocking joinery, and nothing is hidden but the grill magnets. Even the electronics are visible through Plexiglas safety covers.

The labor is horrendous but the results are magnificent; beautiful and reliable with spooky-real imaging and clarity.

All materials are easy to source, but the stator wire is not a common type, so it typically requires a 10,000 foot min-buy.

Amortizing the wire cost to include only the 1,500 ft needed for one pair; the materials run about $1,300 with the Peerless SLS woofers or about $1,550 with the Eminence Kappa-Lite woofers, and about 125 hours labor, excluding jigs.

The required tools are a table saw, router, drill, router circle jig, finger-joint jig, wire stretching/stator assembly jig, diaphragm tensioning jig, and a flat work table. All jigs were shop-made and a drawing of the wire-stretching/stator-assembly jig is freely available upon request.

Project Photos &Videos:

MkIII Reveal Video

MkIII Build Photos

MkIII Wire Stator Build

MkIII Panel Assembly

MkIII speaker with front & rear magnetic grills:

Jazzman MkIII Playing:

*******************************

The Basics

How do they work?

The Basics

How do they work?

If your hair has ever stood on end while unloading a clothes dryer, then you've felt the same force that drives an electrostatic loudspeaker (ESL).

An ESL is a push/pull motor consisting of a thin, conductive Mylar diaphragm suspended in an electric field between two conductive screens called stators.

A high-voltage DC power supply puts a bias voltage on the diaphragm which is reacted on by AC voltages applied to the stators.

The music output from an audio amplifier, routed thru a voltage step-up transformer, applies the driving AC voltages to the stators, and the ultra-light diaphragm responds with exquisite fidelity.

Stators can be made from just about any conductive material, including perforated sheet metal, conductive-coated plastic, wires, metal rods or even bug screen.

My ESL Journey

My first ESLs used flat, perforated metal stators which gave great 'slam' and imaging but were highly directional.

The next generation stators used segmented welding rod conductors, and had switch-selectable wide and narrow dispersion modes. These had a nice, balanced sound but were not aesthetically pleasing.

Finally, my newest panels are more finely segmented for optimal dispersion, and they have beautiful oak-lattice-supported wire stators that sound and look like fine musical instruments.

Flat perf-metal panels (link to build page) are by far the easiest to build and they sound fantastic in the sweet spot. They are also directional in the extreme, prone to arcing if the stators are not perfectly prepared and coated, and require a very stable amplifier to drive their all-capacitive load.

Welding rod panels (link to build page) These were my first foray into electrical segmentation and I only built one pair. It was a fun project with switch-selectable wide and narrow dispersion modes, but they were a pain to build and there are better options that welding rods, so I would not build them again or recommend them.

Insulated wire panels like the ones shown on this page are now my preferred choice. They are super-reliable and easily segmented for tailored dispersion, balanced response and easy amp load. They are also time-consuming to build and require a relatively elaborate jig to stretch the wires.

I opted for solid core wire that, once stretched, holds itself straight without having to be under tension.

I opted for solid core wire that, once stretched, holds itself straight without having to be under tension.

Some builders prefer to use stranded wire, which does not have to be stretched but needs a bit of tension to keep it straight, and therefore requires a stouter structure to support that tension.

More to come on electrical segmentation, but first; my personal

home stereo speaker:

The Jazzman Mk III ESL

home stereo speaker:

The Jazzman Mk III ESL

Dimensions: 67”H x 14.5” W x 15"D, weight about 50 lbs

Woofer(s): Peerless SLS 12 in H-baffle OB

Woofer(s): Peerless SLS 12 in H-baffle OB

Upgrade: Eminence KappaLite 3012LF (with subs)

Stators: Segmented wire type, 10.5” x 46.5” active area

Wires: UL-1061 / 20AWG / SRPVC / solid copper

Wire spacing: 11 wires/inch, 42% open area

Diaphragm: 6-micron Mylar C / Licron Crystal coating

Bias supply: 3.2kVDC Cockroft-Walton cascade

Transformers: (2) 50VA 230V/2x6V toroidal, 76:1 ratio

Crossover: DBX Driverack V360, 265Hz @ 24db/Oct

Dispersion

Wavelengths shorter than a speaker’s radiating width tend to beam rather than spread out (this is why tweeters are small). Flat-panel ESL’s beam excessively because they have to be large to offset their limited excursion and dipole roll-off, so the resulting 'head-in-a-vise' tiny sweet spot is better for solo listening at the focus but not so good for entertaining guests, where wider dispersion is preferable.

A typical way to widen an ESL’s dispersion is by curving its panel, and thereby its radiated wavefront. Segmented ESLs uses a flat panel and curve the wavefront electrically, using discrete stator conductors driving discrete zones on the diaphragm.

Below is a post by Steve Bolser on the DIY Audio Forum which compares the dispersion patterns of unsegmented flat panels, curved panels and segmented flat panels:

More About Electrical Segmentation

Stators: Segmented wire type, 10.5” x 46.5” active area

Wires: UL-1061 / 20AWG / SRPVC / solid copper

Wire spacing: 11 wires/inch, 42% open area

Diaphragm: 6-micron Mylar C / Licron Crystal coating

Bias supply: 3.2kVDC Cockroft-Walton cascade

Transformers: (2) 50VA 230V/2x6V toroidal, 76:1 ratio

Crossover: DBX Driverack V360, 265Hz @ 24db/Oct

Dispersion

Wavelengths shorter than a speaker’s radiating width tend to beam rather than spread out (this is why tweeters are small). Flat-panel ESL’s beam excessively because they have to be large to offset their limited excursion and dipole roll-off, so the resulting 'head-in-a-vise' tiny sweet spot is better for solo listening at the focus but not so good for entertaining guests, where wider dispersion is preferable.

A typical way to widen an ESL’s dispersion is by curving its panel, and thereby its radiated wavefront. Segmented ESLs uses a flat panel and curve the wavefront electrically, using discrete stator conductors driving discrete zones on the diaphragm.

Below is a post by Steve Bolser on the DIY Audio Forum which compares the dispersion patterns of unsegmented flat panels, curved panels and segmented flat panels:

More About Electrical Segmentation

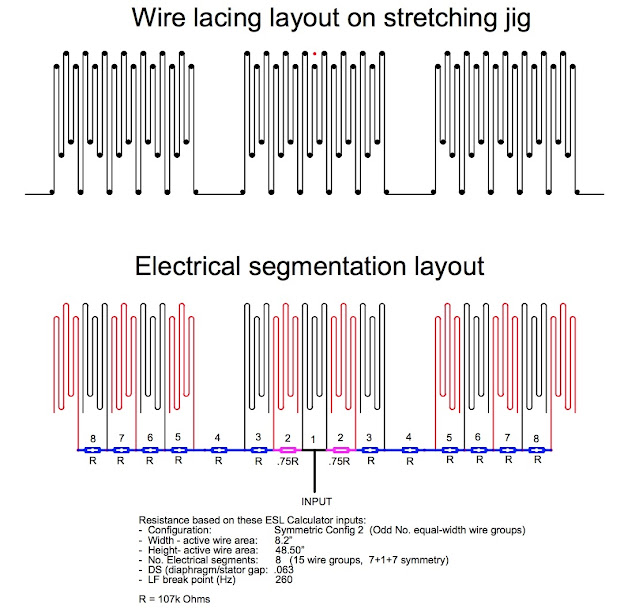

See the Electrical Segmentation Layout and Schematic (below)

The ESL panel employs symmetrically segmented wire stators that function as a line source projecting a cylindrical wavefront.

Each stator has 90 insulated copper wires arrayed in 15 six-wire groups and powered as eight discrete sections with 7+1+7 symmetry. That is, one center wire group and seven left/right paired groups arrayed symmetrically on either side.

The center wire group (Section 1) connects directly to the amplifier interface and receives the full audio bandwidth above the crossover frequency. The left/right paired wire groups (Sections 2-8) are powered in series from the center wire group, through resistors inserted between the wire groups.

The center wire group (Section 1) connects directly to the amplifier interface and receives the full audio bandwidth above the crossover frequency. The left/right paired wire groups (Sections 2-8) are powered in series from the center wire group, through resistors inserted between the wire groups.

These resistors in series, coupled with the wire group capacitances in parallel, form a series of low pass filters which progressively chop off the upper frequencies toward the panel edges. Furthermore, the charging times of the wire group capacitors sequentially shift the phasing to curve the wavefront.

As driven by the segmented stators, the widths of the diaphragm's radiating zones do not exceed the radiated wavelengths, so all frequencies spread out in a curved wavefront giving wide, smooth-trending dispersion.

The resistor values were derived using Steve Bolser's Excel spreadsheet calculator: Segmented ESL Calculator

Mk III Stator - Wire Lacing & Segmentation Scheme:

MkIII Schematic:

Guidelines for Symmetrically Segmented Wire Panels (hybrid ESL only):

· Diaphragm-to-stator gap (d/s): 0.063” (+.015/-.000)

· Span between diaphragm supports: 70-100 x d/s

· Wires: 18-22 AWG single-strand copper, PVC, XLPVC or SRPVC insulation only

· Max span between wire supports (wire gauge/inches): 22/2, 20/3, 18/4

· Wire O.D. (insulation included) should not exceed d/s

· Gap between wires (insulation-to-insulation) should not exceed d/s

· Ideal (max output) open area: 42% (gap/OD)

· [Down to 12mm width] more/narrower wire groups = wider/smoother dispersion

· Transformer(s) power/ratio (each speaker): 100-160VA / 50-100:1

· Bias voltage: 1.8kV – 4kV

· X- over frequency/filter slope: >200Hz / 24db

Building the Wire Stators

Once the panel design is set, the next step is building the stators.

It isn't necessary to build an elaborate stator jig like mine, but it does make it easier.

My friend Aleksandr in Belarus built stators identical to mine using small nails driven into a work table for the pins, and then he pulled the wires taught around the pins manually, applying about 25 pounds of pull on each wire, and then glued the wooden support lattice over the taught wires.

I opted to build a special jig to assemble my stators in. The following instructions apply if using a jig:

Stretching the single-strand copper wires to just beyond their plastic yield point (about 1% elongation) renders them perfectly straight, and they then remain straight when subsequently relaxed.

When turning the jig's jack-nuts to stretch the wires, the turning resistance increases progressively until the copper wires reach their plastic yield point, and then dramatically lessens. The wires are then sufficiently stretched.

The wire loops in my stators were stretched from their initial length of 48.0" to their final length of 48.5", which is about 1% elongation.

An important feature of the jig is its reference platform which sets the stator wires, wire glue lines, and frame rails perfectly in-plane flat, to ensure that the critical diaphragm-to-stator gap will be perfect.

Stretching ninety 20-gauge wires at once requires a strong jig and about 4,000 pounds of force. The jig has a ¾ MDF platform mounted in a stout frame cut from yellow pine 4x4’s. The wire loops wrap over .063 diameter x .250 length steel pins inserted half depth into drilled 3/16” aluminum plates. The pins are angled 3 degrees from vertical to hook the wires.

One pin plate is stationary and the opposite moveable pin plate bolts to a 3/16 steel subplate that’s welded to two 3/4 x 12 all-thread jack rods. Turning the coupling nuts on the jack rods pulls the movable pin plate to stretch the wires.

Before stringing the wires, wax paper coated with liquid car wax is laid down over platform to prevent the wires from bonding to the jig when gluing the support lattice onto the wires. The car wax helps the wax paper peel away cleanly from the completed stator.

Note: For .052" diameter wires spaced 11 wires/inch; the gap between wires would be about 1mm (.042"). However; 1mm diameter pins proved to be too weak to resist bending over, so had to step up the pin diameter to 1/16" (.063").

To set the correct 11/inch wire spacing during glue-up, I used 3D printed comb guides. On my earlier speaker builds I used 5/8"-11 TPI all-thread rods to set the wire spacing but the new self-centering 3D printed guides are much easier.

Stator Lattice Stain & Clearcoat

Before assembling the stators, the oak lattice details were temporarily fitted together without glue, and then laid out on saw horses (wire contact surface down) for spraying on the wood finishes.

Only the exterior surfaces were finished. Great care was used to avoid overspray on the underside surfaces which contact the wires and spacers.

An oil based stain (50/50 mix of natural + golden oak) was then sprayed on in a couple of very light mist coats (not wet, to avoid stain seeping into the interlocking bond surfaces).

The stain was allowed to dry overnight and then a couple of mist coats of clear satin polyurethane were applied, and allowed to dry.

The lattices were then disassembled in preparation for building the stators.

Building the Stators

The wires are supported by an interlocking oak lattice which is assembled and glued down over the wires, in the stretching jig.

After stretching the wires and before gluing the slats down over them, most of the wire tension was relaxed to prevent preloading and warping the stator. The jig's jack nuts are then re-tightened using hand-force only, to apply just enough tension to keep the wires straight. E6000 glue was used for both the wood-to-wood and wood-to-wire bonds.

First the wax paper and vertical lattice rails were laid down in the jig, then the wires were laced around the pins, next the 3D- printed wire guides were installed, and finally the interlocking horizontal slats were glued down over the wires.

First the wax paper and vertical lattice rails were laid down in the jig, then the wires were laced around the pins, next the 3D- printed wire guides were installed, and finally the interlocking horizontal slats were glued down over the wires.

An earlier method to hold wire spacing used lengths of 5/8-11 TPI all-thread rods as comb-guides (see photo below).

Below: Alternate method- all-thread rod wire guides

Diaphragm Spacers

Double-sided tape spacers bond the diaphragm to the stator and set the diaphragm-to-stator gap (d/s) at .063”.

Double-sided tape spacers bond the diaphragm to the stator and set the diaphragm-to-stator gap (d/s) at .063”.

The vertical lattice rails are flush with the wires and their spacers are 0.063" thickness 3M double-sided urethane foam tape; 3/4" wide on the side rails and 3/8" wide on the center rails.

The horizontal end rails anchor the wire end-loops with glue bonds. The end spacers consist of (1) .047" thick x 1" wide x 10.5" length polycarbonate shim bonded onto the wires with E6000 glue, plus (1) layer of .015" x 1" wide 3M UHB double-sided foam tape over the shim (0.062" total).

The double-sided tape spacers bond the diaphragm to the stator instantly with minimal fuss.

Diaphragm

The 6-micron Mylar C diaphragm is vertically sectioned into equal thirds for stability and tensioned to 1.0% elongation using a pneumatic bike-tube jig. The jig is an MDF platform sized two inches longer and wider than the stator and two inches high with all edges rounded over to 0.50” radius, sanded smooth and dusted with baby powder to prevent snagging the delicate diaphragm film. A 700mm x 35mm Schrader valve-type bike tube is stretched around its perimeter.

The Mylar film is wrapped over the jig and secured on the backside with double-sided tape. Inflating the bike tube with a hand pump tensions the diaphragm. Tension is gaged by first marking reference points on the diaphragm exactly 12 inches apart using a fine-tip felt pen. As the tube is inflated, the target elongation is reached when the distance between the reference marks reaches 12 1/8 inches.

For my panels' span between supports, 1% elongation provided enough tension to prevent driving the diaphragm into the stators at high volume, yet kept the drum head resonance low enough to set the crossover frequency below the ear-sensitive midrange region. I would not use less then 1% stretch on the diaphragm.

Since the amount of elongation/tension required to stabilize the diaphragm is dependent on the span between supports, the elongation would vary for different spans-- 1% would not work for all panels.

The stator is then pressed into place over the diaphragm to affect the bond.

Diaphragm Coating

The diaphragm must be made conductive enough to hold a bias voltage yet resistive enough to slow the charge migration across its surface. This is achieved with one coat of Licron Crystal ESD conductive coating.

Diaphragm

The 6-micron Mylar C diaphragm is vertically sectioned into equal thirds for stability and tensioned to 1.0% elongation using a pneumatic bike-tube jig. The jig is an MDF platform sized two inches longer and wider than the stator and two inches high with all edges rounded over to 0.50” radius, sanded smooth and dusted with baby powder to prevent snagging the delicate diaphragm film. A 700mm x 35mm Schrader valve-type bike tube is stretched around its perimeter.

The Mylar film is wrapped over the jig and secured on the backside with double-sided tape. Inflating the bike tube with a hand pump tensions the diaphragm. Tension is gaged by first marking reference points on the diaphragm exactly 12 inches apart using a fine-tip felt pen. As the tube is inflated, the target elongation is reached when the distance between the reference marks reaches 12 1/8 inches.

For my panels' span between supports, 1% elongation provided enough tension to prevent driving the diaphragm into the stators at high volume, yet kept the drum head resonance low enough to set the crossover frequency below the ear-sensitive midrange region. I would not use less then 1% stretch on the diaphragm.

Since the amount of elongation/tension required to stabilize the diaphragm is dependent on the span between supports, the elongation would vary for different spans-- 1% would not work for all panels.

The stator is then pressed into place over the diaphragm to affect the bond.

Diaphragm Coating

The diaphragm must be made conductive enough to hold a bias voltage yet resistive enough to slow the charge migration across its surface. This is achieved with one coat of Licron Crystal ESD conductive coating.

The periphery 1/8" of the diaphragm was masked off with painters tape to prevent creating a conduction path to the stator edges. The Licron Crystal was then sprayed on in one “just wet” coat and allowed to dry for eight hours before assembling the panels. The coating dries to a pale blue-gray, almost clear coating about 2-microns thick with E7-E9 resistance.

Video: Diaphragm tensioning and panel assembly

Bonding stator to diaphragm on bike tube jig:

Below: Bonded diaphragm ready for conductive coating

Charge Ring

The charge ring is ¼ inch wide copper foil tape applied to the periphery of the rear stator, centered on the foam tape spacers. The wire lead from the DC biasing power supply is soldered to it and when the front and rear stators are mated together, the charge ring contacts and conducts the bias voltage onto the diaphragm.

Rear stator with spacers & charge ring:

Completed front & rear stators ready for assembly:

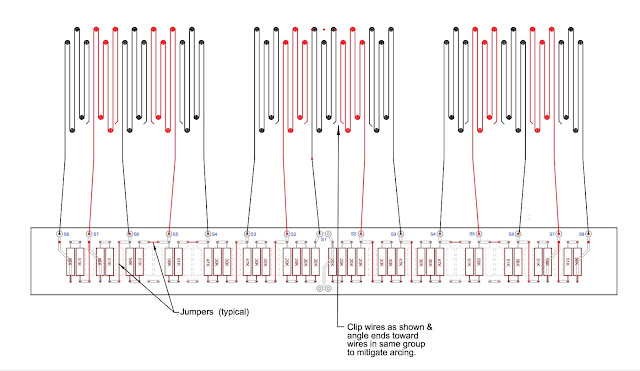

RC Segmentation Network (Jazzman MkIII)

The RC (resistor/capacitor) filter network tailors the panel's dispersion pattern electrically, by attenuating the frequencies and phasing of the music signals driving the separate wire groups.

Video: Diaphragm tensioning and panel assembly

Bonding stator to diaphragm on bike tube jig:

Below: Bonded diaphragm ready for conductive coating

Charge Ring

The charge ring is ¼ inch wide copper foil tape applied to the periphery of the rear stator, centered on the foam tape spacers. The wire lead from the DC biasing power supply is soldered to it and when the front and rear stators are mated together, the charge ring contacts and conducts the bias voltage onto the diaphragm.

Rear stator with spacers & charge ring:

Completed front & rear stators ready for assembly:

RC Segmentation Network (Jazzman MkIII)

The RC (resistor/capacitor) filter network tailors the panel's dispersion pattern electrically, by attenuating the frequencies and phasing of the music signals driving the separate wire groups.

The wire segmentation scheme and network resistor values were derived using Steve Bolser's Segmented ESLCalculator spreadsheet.

From the spreadsheet options, I chose Symmetric Config 2, both stators segmented, in eight electrical sections, and a low-cutoff of 260Hz. For my panel the spreadsheet calculated 107kΩ for R, with R/9 resistance on the section one wire groups, 0.75R on section two wire groups, and R on sections 3-8 wire groups.

It’s common practice to move/reflect the section one resistances to the primary side of the transformer to protect against core saturation (see Schematic, damping resistor R1). Reflecting section one's R/9 resistance across an ideal transformer would divide the sum by the turns ratio squared (4.6Ω in this case). However, placing this much resistance on the primary side of a real transformer, interacting with its winding resistance, leakage inductance, and winding capacitance, would result in a significant roll off of high frequencies down into the audio band.

The transformer's winding capacitance adds to the load capacitance and its leakage inductance combines with the load capacitance to generate an ultrasonic resonance peak in the frequency response and rapid roll off above it. Coincident with this response peak is an impedance minimum which can be a difficult load for the amplifier.

It’s common practice to move/reflect the section one resistances to the primary side of the transformer to protect against core saturation (see Schematic, damping resistor R1). Reflecting section one's R/9 resistance across an ideal transformer would divide the sum by the turns ratio squared (4.6Ω in this case). However, placing this much resistance on the primary side of a real transformer, interacting with its winding resistance, leakage inductance, and winding capacitance, would result in a significant roll off of high frequencies down into the audio band.

The transformer's winding capacitance adds to the load capacitance and its leakage inductance combines with the load capacitance to generate an ultrasonic resonance peak in the frequency response and rapid roll off above it. Coincident with this response peak is an impedance minimum which can be a difficult load for the amplifier.

When series resistance is added on the primary side it dampens this resonance peak. However, as previously noted, too much resistance over-damps the resonance and can roll off the audible highs.

The spreadsheet assumes an ideal transformer is used, so it doesn’t calculate the effect of resistance on the primary side of a real transformer. The general guidance is to omit the section one resistors on the secondary side, add a 1Ω series resistor on the primary side and give it a whirl. My panels sounded really good with this initial setup.

From there the only tuning, if any, is adjusting the series resistance on the primary and/or the first two stator sections to dial in the treble response. Less resistance increases treble and visa versa.

The schematic and parts list show the spreadsheet values except with section one resistors omitted and reflected as 1Ω on the primary. I think this would be optimal for most listeners.

All remaining resistors on the secondary side are 2W, 500V in series. Wattage and voltage are highest across the first resistors and decrease down the line. Based on R=107kΩ; Multiple resistors are ganged to spread the load as follows:

The spreadsheet assumes an ideal transformer is used, so it doesn’t calculate the effect of resistance on the primary side of a real transformer. The general guidance is to omit the section one resistors on the secondary side, add a 1Ω series resistor on the primary side and give it a whirl. My panels sounded really good with this initial setup.

From there the only tuning, if any, is adjusting the series resistance on the primary and/or the first two stator sections to dial in the treble response. Less resistance increases treble and visa versa.

The schematic and parts list show the spreadsheet values except with section one resistors omitted and reflected as 1Ω on the primary. I think this would be optimal for most listeners.

All remaining resistors on the secondary side are 2W, 500V in series. Wattage and voltage are highest across the first resistors and decrease down the line. Based on R=107kΩ; Multiple resistors are ganged to spread the load as follows:

Section 1: none (reflected as 1Ω on TFMR primary)

Sections 2 (.75R): (4) 20kΩ

Sections 3, 4: (2) 30kΩ + (1) 47kΩ

Sections 5-8: (1) 56kΩ + (1) 51kΩ

MkIII RC network resistors:

Segmentation resistor connections to generic PCB:

The ESL panel requires an interface to its amplifier; this consists of a high voltage DC power supply to bias the diaphragm, and transformers to step up the amplifier's drive voltage to the stators.

Unlike most commercial hybrid ESLs which typically have passive crossover and EQ components in the interface, my speakers use a DSP crossover upstream of the amps, so my interface is much simpler.

Each interface uses two 50VA 230V/2x6V toroidal transformers wired in tandem, with 6V windings in parallel on the primary side and 230V windings in series on the secondary side, giving a 76:1 step-up ratio. The DC biasing supply uses a floating ground, center tapped between the transformers' 230V windings.

The DC biasing supply is a simple, reliable half-wave rectifier/voltage multiplier, outputting 3.25kV. This is powered by 115VAC mains current into a 115V/230V transformer feeding a diode/capacitor ladder with a 20MΩ charging resistor at the output. The charging resistor stabilizes the charge on the diaphragm and limits the potential current flow that might otherwise sustain any arcing to the stators.

Mk III Amp/panel interace:

Bass Section - Jazzman Mk III

Each interface uses two 50VA 230V/2x6V toroidal transformers wired in tandem, with 6V windings in parallel on the primary side and 230V windings in series on the secondary side, giving a 76:1 step-up ratio. The DC biasing supply uses a floating ground, center tapped between the transformers' 230V windings.

The DC biasing supply is a simple, reliable half-wave rectifier/voltage multiplier, outputting 3.25kV. This is powered by 115VAC mains current into a 115V/230V transformer feeding a diode/capacitor ladder with a 20MΩ charging resistor at the output. The charging resistor stabilizes the charge on the diaphragm and limits the potential current flow that might otherwise sustain any arcing to the stators.

Mk III Amp/panel interace:

I originally used a Peerless SLS 12" woofer, which is a great OB woofer that just does everything well. I consider it the best woofer out there at its modest price point.

I currently use an Eminence Kappalite 3012LF woofer. Its tight, clean top end matches well with the ultra-fast ESL, and it has huge mid-bass punch, but the bottom end rolls off higher, so it's best used with subs.

What can I say about the Ripol subs? The bass messiah has come down from heaven with the cleanest, most musical subs I've ever heard - I would not want anything else.

Power & Control - Jazzman MkIII Speaker

The speaker pair is vertically bi-amplified, using a DBX Driverack Venu 360 digital crossover feeding a pair of vintage Carver TFM-25, 225 watts/channel stereo amplifiers. The PA2 Driverack is also a good option (lower cost than the Venu 360).

*******************************************************

RiPol Subs

Bass that rises from nowhere and recedes back to nowhere:

Mervyn's Eros Clone speaker build - June 2019:

The exquisitely crafted speakers shown below were built by my online collaborator Mervyn Tims. Segmented wire panels mated to a 10" Aurum Cantus woofer in a compact transmission line built with amazing skill-- has to be a killer combo.

I'm dying to hear them!

The exquisitely crafted speakers shown below were built by my online collaborator Mervyn Tims. Segmented wire panels mated to a 10" Aurum Cantus woofer in a compact transmission line built with amazing skill-- has to be a killer combo.

I'm dying to hear them!

My friend Martin and I built this speaker together, for Martin. We call it the 'Audi' because the speaker pair needed to fit into the back/trunk of Martin's 2008 Audi A4 for transporting. This speaker became the prototype for the Jazzman Mk III.

The transmission line woofer box/frame was built in 2008.

The original perf metal stators were updated to segmented wire type in 2015.

Bass Section - Beam Splitter Speaker

The woofer box is a single-fold, tapered transmission line stuffed with 0.5lbs/Ft3 of polyfil. The line’s sectional area is 125% of the woofer’s cone area at the front, tapering to 100% of the same at the terminus. The cabinet is ¾” MDF sheathed in 5mm red oak plywood and the panel frame is solid red oak.

To minimize the woofer box’s profile and footprint, its volume extends upward, behind the stat panel, and its frontal surfaces are angled to form a V-shaped “beam splitter” which deflects the panel’s rearward sound out the open sides of the speaker rather than back to the diaphragm.

When designing the bass section I followed Roger Sanders’ lead and opted for a transmission line enclosure and a woofer with low moving mass, low QTS, and low inductance coupled with a very strong motor magnet. The ideal matching woofer doesn’t exist of course, but low inductance takes priority and the Aurum Cantus AC250 MKII I chose works pretty well.

Below: Bob Carver loves my speakers!

Cellphone Video from Carverfest 2016

The woofer box is a single-fold, tapered transmission line stuffed with 0.5lbs/Ft3 of polyfil. The line’s sectional area is 125% of the woofer’s cone area at the front, tapering to 100% of the same at the terminus. The cabinet is ¾” MDF sheathed in 5mm red oak plywood and the panel frame is solid red oak.

To minimize the woofer box’s profile and footprint, its volume extends upward, behind the stat panel, and its frontal surfaces are angled to form a V-shaped “beam splitter” which deflects the panel’s rearward sound out the open sides of the speaker rather than back to the diaphragm.

When designing the bass section I followed Roger Sanders’ lead and opted for a transmission line enclosure and a woofer with low moving mass, low QTS, and low inductance coupled with a very strong motor magnet. The ideal matching woofer doesn’t exist of course, but low inductance takes priority and the Aurum Cantus AC250 MKII I chose works pretty well.

Below: Bob Carver loves my speakers!

Cellphone Video from Carverfest 2016

Videos:

Cellphone Video - Audi Speaker at Carverfest 2018

Cellphone Video- Beam Splitter Speaker at Carverfest 2016

Cellphone Video- Beam Splitter Speaker at Carverfest 2016

Jazzman's System (original perf-metal panels)

Cellphone Video on Youtube (perf-metal panels)

Links to other pages on this blog: